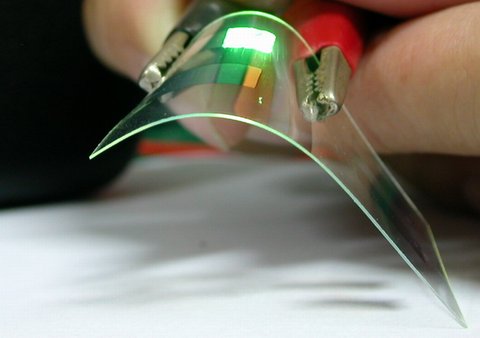

Let’s

dream about a high definition television that is even less than a

quarter inch thick, curved and about 80 inches wide. Moreover, it

consumes lesser power than your normal TV set and it can be rolled up if

you don’t want to use it. You can also carry that TV around wherever

you like. What if we could have a display monitor inbuilt in our

clothing? Does it look real or just a dream? Well, these devices can be

existent in near-term using the recent technology of OLEDs.

Abbreviated for Organic Light Emitting Diode, OLED

is a recently developed display technology in which a layer of organic

compound emits light when electric current runs through it along with a

combination of filters and color refiner to produce high definition

images. It packs in carbon based sheets between two charged electrodes,

comprising of a metallic cathode and a transparent anode. The organic

based films surround hole transparent layer, emissive and electron

transport layer inside it. When current is applied to the OLED cell, the

positive and negative charges remerge in the emissive layer and creates

an electro luminous light. OLED displays are emissive devices and they

work on emitting light rather than modulating or reflecting the light.

A glimpse on OLED technology

The sheets used in OLED devices are prepared from

organic carbon based materials that illuminates when current is applied

through them. They are much more efficient and simpler to use than LCDs

as they are not dependent upon backlight and filters. They provide a

beautiful picture quality with amazing clarity. They also provide

brilliant colour features; have a relatively fast response rate and a

wider range of viewing angles. They are also used for making OLED

lightings.

This technology was made-up in early 1980s. It was

further developed to replace LCD technique because OLED technology is

comparably brighter, thinner and lighter than LCDs. They also consume

lesser power than LCDs and offers higher contrast features. The most

attractive advantage that it possesses over LCDs is that they are

comparably cheaper to manufacture and hence it is cost effective.

Working of OLED

OLED technology works on a very simple principle.

Whenever a current is applied to the electrodes, an electric field gets

developed around it as a result, the charges start moving in the device.

Electrons escape from the cathode and holes move from anode in reverse

direction. The electrostatic force brings the electrons and the holes

together and they form a photon which is a bound state of electron and

hole. This recombination of charges develops photon with a given

frequency that is given by the energy gap that gets formed between the

LUMO and HUMO levels of the emitting molecules. This electrical power

that is applied to the electrodes gets converted into light that is

radiated out from the device.

Different materials are used to produce different

colours of light and the colours combine to form a white source of

light. Generally, the anode material is made up of Indium tin oxide

because it is transparent to the visible light and has a high work

function. The material helps to promote injection of holes into the HOMO

level of organic layer. Materials like barium and calcium are commonly

used for making cathode electrodes as they have lower work function and

they can promote injection of electrons into the LOMO level of organic

layer. These materials also required to be coated by metals like

aluminium as they are very reactive in nature and often need a

protective sheet over them.

Materials used in OLEDs

The basic structure of an OLED contains a cathode

for introducing electron, an emissive layer and an anode for removing

electron out of it. Although the modern OLEDs contain many more layers,

yet the elementary functionality remains the same in all the types of

OLEDs. There are several types of OLED materials that are used in

manufacturing of OLED. The most fundamental division is of small

molecule OLEDs and large molecule OLEDs. All the commercially utilised

OLEDs are small molecule based, which is called SMOLED. They perform

better and efficiently. The emitter materials that are used in OLEDs are

fluorescent or phosphorescent. The fluorescent materials have a longer

lifespan although they are less resourceful than the later one. Most of

the OLEDs use phosphorescent materials as they provide better services

and longer run.

AMOLED and PMOLED are the terms related to the

display of an OLED. A PMOLED has limited range and resolution although

they are economical than AMOLED. These displays are very complicated to

manufacture but they are efficient to use and can also be given larger

dimensions. PMOLED displays are utilized in producing smaller devices

while AMOLED displays are used in television sets, tablets and

smartphones.

Applications of OLEDs

OLED technology is used in commercial applications

of mobile phones, digital media players, car radios, digital camera,

television etc. Portable displays are used in the mechanism so the lower

lifespan is no more an issue in this purpose. It can also be used for

all-purpose illumination as well as for displays and rear light sources

in LCD displays, traffic signals, emergency signals or automotive

applications.

Advantages of OLED technology

OLED technology has really opened a widen gates

for many advancements and developments in the field of machinery, tools

and electronic equipments. It offers following benefits:

- It does not use any liquid material and comprises of solid construction, as a result it offers a better resistance.

- They can be viewed from any angle and gives a wide range of enjoying the view. In spite of this, we never feel any distortion in the screen and any drawback in the quality.

- It can possess thickness as low as 1 mm which is even less than half of the thickness of LCDs. As a result, they are lighter in weight.

- The response time of OLEDs is 1/1000 of LCDs.

- It can work in lowest temperature possible even if it is minus 40 degree.

- It is cost efficient as the manufacturing is reasonable as well.

- They give brighter light and consume lower power.

- It offers higher efficiency and larger area sources.

- Flexible display and tuneable emission.

Disadvantages of OLED technology

With the countless advantages, we have some flaws and drawbacks of the technology as well that are mentioned hereunder:

- The colour purity crisis is an inadequacy in the device as it finds difficult to display fresh and rich colours.

- It can get easily damaged by water.

- Large quantity productions of large size screens are not obtainable.

- It usually comes up with life span of 5000 hours which is much lower than LCDs.

- The most prominent drawback of OLEDs are they cannot be seen in the presence of direct sunlight.

The developers have tried making positive changes

in these drawbacks and thus have developed OLEDs having longer lifespan.

Red and green OLED has lifespan of 46000 to 230000 hours while blue

OLEDs have lifespan of around 14000 hours. Larger OLED panels have also

been produced.

Challenges faced by OLEDs

Although the technology has taken a great leap in

the recent times, there are still several challenges that are being

faced by OLED industries. They are listed as follows:

- Material lifespan of OLEDs

- Soluble OLED performance

- The lighting capacity expansion of OLEDs

- Colour balance.

- Water damage.

The recent developments in OLED technology

OLED technology has been widely used in recent

years and it is quite successful as per the study. Samsung is the

leading producer of AMOLED displays today. It is making over 200 million

of displays every year and is about to enlarge the production

capability of their manufacturing very soon. It is focussing on smaller

displays of 5-10 inch which are used in smartphones and tablets these

days.

LG is also manufacturing OLEDs of larger display

panels. It has used OLEDs for producing Television units of 55 to 77

inch display.

Even if both the companies have produced enough

number of OLEDs every year, still the production volume has been

relatively slower. As reported by both the companies about expanding

their production capacities, the expectations for larger production of

OLEDs have been widened and the public is also expectant about any new

product launch.